British Non-Ferrous Metals Research Association

(c) Antique Metalware Society

Small extracts can be used with acknowledgements to 'Oldcopper.org' website.

Helpful comments are very welcome.

(This is an expanded version of the article prepared originally for Wikipedia)

( I started work with the BNF on the 25th February 1952 as a laboratory assistant and gained a wealth of knowledge and experience before leaving in 1966 to join Delta Enfield Rolling Mills. The main building in Euston Street, NW1 is now the MIC Hotel and Conference Centre.)

The Association was formed in 1920 by members of the British Non-Ferrous Metals Federation which represented the commercial interests of British manufacturers of coppers and copper alloys, lead, zinc and other non-ferrous metals and their alloys, latterly including titanium. The purpose was to carry out technical research on behalf of members on topics of commercial interest to their industry. The name was abbreviated officially to B.N.F.M.R.A. but the organisation was normally known as ‘The BNF’ during its life and a BNF logo in a shield was used on many publications. Robert Hutton was appointed director in 1921 and expanded it to achieve a world-wide reputation. During the lifetime of the laboratories, many other staff had reputations that were recognised and respected throughout the world.

Membership

The 600 or so subscribing members formed Industry Committees representing each of the main metal interests which discussed and agreed the topics for technical work to be done and a Council that controlled overall finances. Initially there was an annual government grant towards the work but this was changed to support funding for individual projects. When topics for research were agreed and funded by the industry they were then submitted to the government for approval of matching support funding but after the 1960s policy dictated that this became more and more difficult to obtain. The BNF also took on some contracts wholly sponsored by organisations which included some government departments. Individual technical enquiries from members were answered on a free and confidential basis.

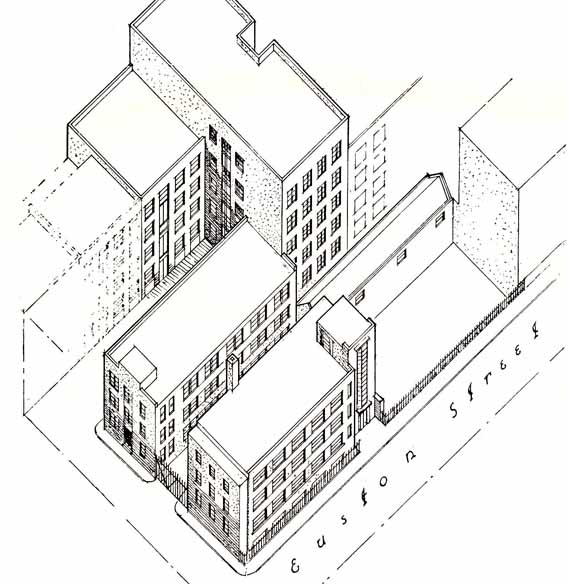

An Ariel view of the laboratories drawn before the area to the right of the main entrance was rebuilt during the 1950s.

Laboratories

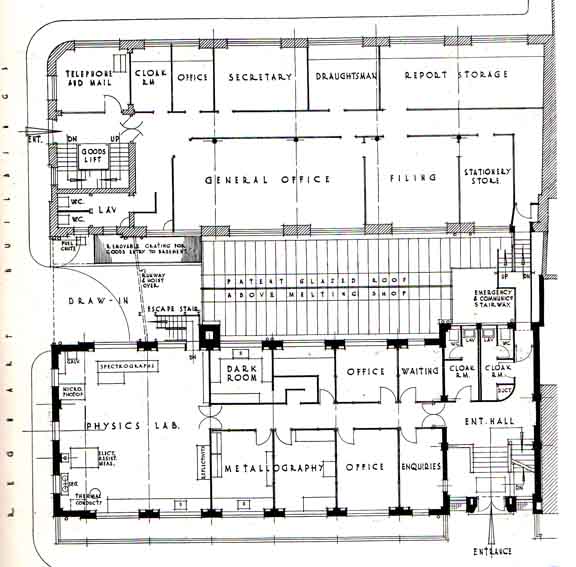

For many years after it was opened in 1939 the work was carried out in laboratories fronting on Euston Street, London, NW1. These included three parallel four-story blocks of laboratories and offices with the basements being used for the heaviest equipment and for storage of samples. The laboratories were grouped in specialist sections, including Chemistry, Corrosion, Creep Testing, Electrodeposition, Fatigue Testing, General Metallurgy, Information Library, Mechanical Testing, Melting and Casting, Members Liaison, Metallography, Metal Working, Physics, Spectrography.

Plan of the ground floor in 1939, also before the extension. Other plans show the semi-basement foundry, metal working shop, mechanical testing laboratory and other rooms. Above the ground floor are the first and second floors with more laboratories, the library and offices.

The laboratories were an excellent training ground both for assistants who studied for their qualifications part time and for industrial research experience for recent graduates from universities. Assistants were expected to study for one day and two evenenings each week at college towards professional qualifications. During their training they would occasionally be moved between sections to gain extra practical experience. Recent graduates would gain invaluable experience in industrial research projects. As such, BNF members found that staff could be ideal recruits for industrial work. There were 150-200 staff and the average time for researchers to stay was about three years and they could then be found in industries in Britain and world-wide. From the late 1930s to the 1960s through the war and then post-war recovery the Director was Mr G. L. Bailey with Miss E. M. (Helen) Hills as his secretary.

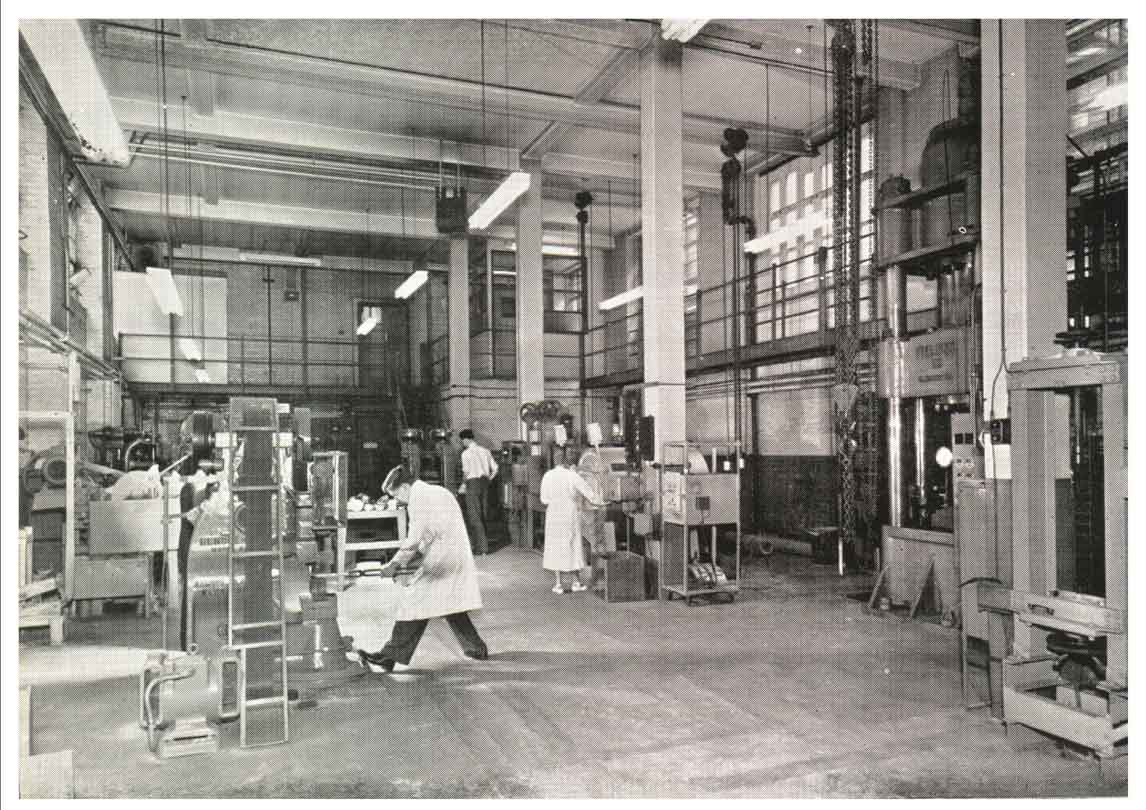

The foundry in clean condition showing the pit furnaces and moulding bench. Later it was extended to move the moulding shop behind where the photographer is standing. The area is now the Attrium bar area of the hotel.

The Metal Working Shop adjoined the foundry in the basement. To the right is the 500 ton extrusion press, to the left a small hammer and in the distance beyond the furnace is the 12" rolling mill. This photo scanned from a BNF publication.

Reports

There was a quarterly report on each research topic presented to the individual research committee and an annual one circulated also to members on request. Final results were compiled as a report that was immediately available to members. After about two years the commercial confidentiality was dropped and a paper was presented at a meeting of the Institute of Metals or other organisation and subsequently published in their Journal. Some researches that had resulted in valuable definitive advancements were then published in book form.

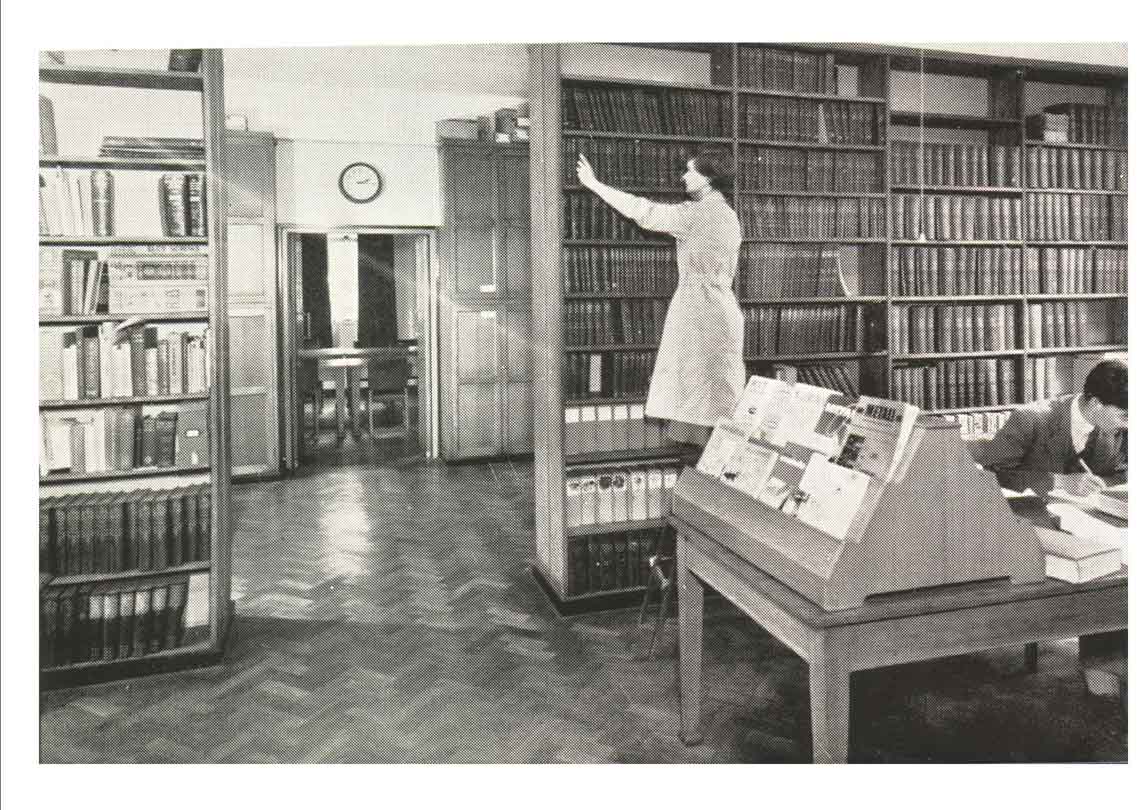

The library had an excellent stock of books, journals and reports. It was on the first floor of the Euston Street building. The big committee room is through the end doors.

Wartime Work

Much of the work done by the BNF during the 1939-45 period was of vital use for the defence industry. This especially included solving many of the corrosion problems of seawater cooled condenser tubes and tube plates that had resulted in many ships being unserviceable and significant improvements in corrosion resistant alloys for seawater pumps and pipe fittings. Work on room temperature creep properties also resulted in the design of some time fuses for explosive devices. No work was ever carried out on active materials for nuclear weapons. Some consultancy work was undertaken on paperwork for new designs.

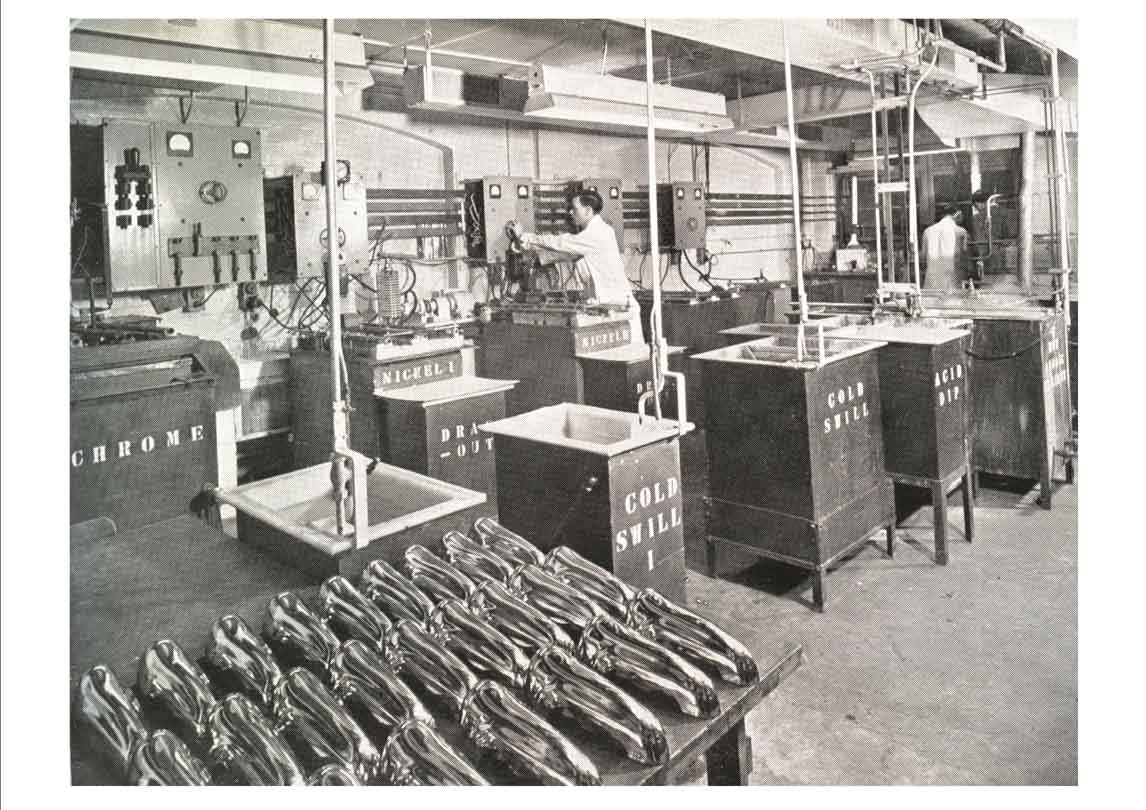

The Electroplating Shop was in the basement beyond the metal working area. In the foreground are plated car bumper overriders that were excellent plating test samples.

The Electroplating Shop was in the basement beyond the metal working area. In the foreground are plated car bumper overriders that were excellent plating test samples.

There has been much publicity about Mrs Melita S. Norwood (née Miss M. S. Sirnis) who joined the BNF in 1937 as a clerk, was eventually promoted to secretary and retired in 1972. As secretary to the Research Superintendent she had access to the papers prepared at the BNF for presentation to the research committees and some contractors. Some of these she chose to copy to Russian intelligence. This information was made use of by them and did occasionally result in one of their research organisations publishing development work on non-ferrous metals similar to and sooner than the BNF in Britain.

The last big reunion of BNF staff was held on the 10th April 1999 at No1, Carlton House Terrace, then home of The Institute of Metals.(Composite by Vic Lucy)

BNF-Fulmer

During the 1970s the BNF became the BNF Metals Technology Centre and moved out of London to a re-developing airfield site at Grove Laboratories, Wantage, Oxfordshire. Recognising globalisation, membership was then opened to companies based overseas. In 1991 the BNF bought Fulmer Research from the Physics Society and was renamed the BNF-Fulmer, then BNF (Fulmer Materials Centre). The laboratories were closed in 1992 with much of the residual material going to ERA Technology, Leatherhead.

References

- BNFMRA ‘Ten years of research for the metal industries: A brief record of progress made by the British Non-Ferrous Metals Research Association, 1920-1930’, 1931

- BNFMRA ‘A Brief Illustrated Description of the Headquarters and Central Laboratories, Regnart Buildings, Euston Street, N.W.1’, 1931.

- BNFMRA ‘The Laboratories Of The British Non-Ferrous Metals Research Association’, 1939

- Sir John Greenly ‘British Non-Ferrous Metals Research Association: 1920-1945’, 1945.

- BNFMRA ‘British Non-Ferrous Metals Research Association 1962’. (Annual Reports were issued each year).

- S.L. Archbutt and W. E. Prythurch ‘Effect of Impurities in Copper’, 1937, BNFMRA

- S. J. Nightingale, ‘Tin Solders: a modern study of the properties of tin solders and soldered joints, BNFMF Research Monographs. No. 1, 1932, second edition 1942.

- D. M. Smith, ‘Metallurgical Analysis by the Spectrograph, BNFMF Research Monographs No. 2, 1933

- R Genders and G. L. Bailey ‘The Casting of Brass Ingots’, 1934, reprinted 1943, BNFMRA.