The Heritage of

John Wilkinson

'King of the Ironmasters'

'Iron Mad Wilkinson'

Our Wilkinson Heritage

Paper given to Broseley Local History Society 3rd March 2011 by Vin Callcut,

It was edited from paper ‘The Industrial and Social Impact of John Wilkinson’

given originally to:

‘Footprints of Industry Conference 3rd-6th June 2009’ - 'Britain as an Industrial Society'

|

Wilkinson’s ‘Trial’ – the First Iron Barge |

Inflation of the Price of Bread Inflation of the price of Copper Inflation of the prices of cast iron |

John Wilkinson (1728-1808)

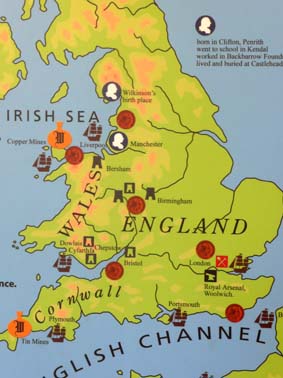

Broseley Ironmaster, Inventor and Entrepreneur Countrywide.

Born July 14th 1728 in Clifton, Cumbria, son of Isaac Wilkinson.

Died July 14th 1808 in Bradley, Staffordshire.

Major achievements:

· Many improvements in the production of iron.

· Use of sound castings for cannon manufacture

· Accurate boring machine for cannon

· Method for making spiral drive grooves (rifling) to improve accuracy of cannon fire

· Method for producing accurate, truly circular cylinders for steam engines

· Major instigator of the use of cast iron for the Bridge at Coalbrookdale

· Promoted use of iron for barge manufacture

· Promoted use of railways for carrying his products down to the River Severn

· Major investor in copper mining and refining

· Investor in other industries including production of lead and chemicals

Abstract

John Wilkinson is recognised as an ironmaster of ability, acumen and energy. Accepting technical challenges, his production methodology was evolved to build an enviable reputation for product quality. He could price his products accordingly. Starting with little capital, he developed business and communication skills that enabled him to convince backers to support his ironmaking enterprises.

He found areas where ironmaking opportunities were apparent and expanded his interests by either takeover or new building. After establishing a sufficiently prosperous share of Britain’s growing ironmaking industry, he expanded into other industries where his expertise and capital would be useful. The copper industry was one that benefitted from his help and also used considerable tonnage of iron in infrastructure and production. The manufacture of lead pipes and chemicals were also of significance. Transport of raw materials, fuels and finished goods on land and by water was vital to his businesses. If profitability became impaired, he could choose to sell out of some businesses and move his capital elsewhere.

In each major area of interest he established a domestic base. His various domestic and agricultural projects made significant differences to local areas.

The paper will examine the way in which the impact of one ironmaster can be assessed. This will include the establishment of business systems and human resources together with the chronology of acquisitions as a majority or minor shareholder and associated projects. His interactions with colleagues will be discussed regarding their common objectives. This will help towards a summary of perceived benefits to the British economy and society.

Introduction

The call for papers for this conference sets out an interesting challenge in calling for an assessment of the impact of the Industrial Revolution on the modern world. Many papers and books have been written establishing the achievements of the leaders of the industrial enlightenment that stimulated the prosperity of the nation. To assess the long term impact means that for each activity the personal and financial benefits would need to be quantified. The individual items would then be adjusted for inflation and totalled to give an overall figure comparable with current money values. In the absence of full records of employees, orders and sales figures, the results have to depend on best estimates.

Many of the published articles and books that refer to John Wilkinson and have been used and acknowledged. The use of any quotation does not imply that it has been verified. The survey of interests cannot be comprehensive; for simplicity and brevity, it omits references to exports, overseas interests and most adversities.

Domestic & Family

John Wilkinson’s family hailed from the English/Scottish border region where life had never been easy and feelings often ran high. Family loyalties were very strong. This background might have influenced his business policies and his probable charming Cumbrian accent would have helped establish his apparent neutrality in negotiations in Southern England. His surname is listed as one of the border reiver families operating during the 16th and 17th centuries who had their own ways of re-distributing wealth. It is an Anglicised form of the Scots surname ‘McQuillan’.

Like Winston Churchill, Richard Branson and other political and industrial leaders since, Wilkinson did not need much sleep. He thought that time spent asleep was time wasted. He preferred to lie, relax and think usefully. He rested holding in his hand a steel ball, poised over a copper bowl. If he dropped off there was a clang of metal on metal that swiftly brought him back to himself[1].

(Click the links to get to the references,

then click the reference link to get back to the text.)

He was known to be careful with his hard-earned money but was prepared to give for good causes[2] and to help out friends in financial problems[3].

Personal circumstances may well have helped guide the mind of John Wilkinson when he was making significant decisions. This is a brief résumé of events. Ironmaster activities are covered under their own sections.

1728 – John born in Cumbria, Isaac, his father was an ironmaster. He was the oldest child. Later came a brother, William (b1744) and three sisters, Mary (married Joseph Priestly), Sarah and Margaret.

1740 – Moved to Backbarrow. Educated at Kendal in the Lake District where the Mines Royal had been established to mine copper.

1754 - John married Ann Mawdsley and moved to Wrexham with her.

1756 – Daughter Mary was born but Ann died soon afterwards. John moved to Broseley.

1762 – Cartel formed between John Wilkinson, Isaac Wilkinson and Abraham Darby for agreed prices for castings for materials for fire-engines, cylinders, bored items and non-bored items[4].

1763 - John married Mary Lee, major shareholder at Bersham ironworks and sister-in-law of Edward Blakeway, one of his partners at Willey, They moved house to ‘The Lawns’ at Broseley.

1774 – Became Burgess of Much Wenlock.

1775 – First steam engine cylinder bored for James Watt.

1776 - His friend Samuel More, Secretary of the Royal Society for Arts, Manufacture and Commerce joined Wilkinson in Birmingham for business meetings and was then Wilkinson’s guest in Broseley. More continued to help promote Wilkinson’s work until his death in 1797[5].

1781 – Wilkinson built a new house at Castlehead, Cumbria, roofing it with his copper.

1785 – He was a key negotiator in setting up and financing the Cornish Metal Company with Boulton, Vivian, Williams and others.

1785 - Helped to form The United Chamber of Manufacturers of Great Britain together with Messrs. Reynolds, Boulton, Watt, Wedgwood and others[6].

1786, aged 58 and still being refused a partnership, there is some friction with Boulton but he still regards Watt with affection[7].

1787 – Launched first iron barge at Broseley.

1787 – He Started minting copper tokens immediately after encouraging Thomas Williams to start production of his Anglesey tokens. He accepted office as High Sheriff of Denbighshire.[8].

1795 – John’s brother William gave details of John’s ‘pirate’ steam engines to Boulton and Watt[9]. They had been built without payment of royalties with tacit agreement of the senior Boulton and Watt. Their sons did not follow this arrangement. This will have reduced still further his chances of being offered a partnership.

1802 - Wilkinson had a daughter, Mary Ann, by Ann Lewis, his mistress at Brymbo. Johnina was born in 1805 and John in 1806 when Wilkinson was aged 78[10]. John Wilkinson also had three nephews, Thomas Jones, William Johnston and Richard Watson.

1806 – His wife, Mary Lee, died at Castlehead.

1808 – Wilkinson died. Ann Lewis lived on at Castlehead with their children.

Colleagues and Friends

A small selection of names shows the very wide variety of colleagues and associated interests that occupied the brain of John Wilkinson.

Anthony Bacon, ironmaster and government contractor.

Mathew Boulton, industrialist.

James Brindley – canal builder

Henry Cort, ironmaster and inventor of the iron puddling process and improvements to rolling mills[11].

Richard Crawshay - ironmaster and promoter of canals[12]

Abraham Darby III – ironmaster

Erasmus Darwin polymath and grandfather of Charles Darwin[13]

Samuel More – Secretary, Royal Society for Arts, Manufactures and Commerce, and good friend.

Thomas Farnolls Pritchard – architect and inventor.

William Reynolds - ironmaster

Thomas Telford – County Surveyor and engineer

John Vivian – mining and copper-smelting entrepreneur[14].

James Watt – inventor and mechanical engineer

Josiah Wedgwood - designer and manufacturer of pottery[15]

William Wilkinson – younger brother

Thomas Williams – solicitor, owner of copper mines and associated industries and friend[16].

For a quick comparative measure with the spread of activities of contemporary ironmasters, it is interesting to look at the index to Trinder’s classic study of the Industrial Revolution in Shropshire. The three Abraham Darbys have a 60mm depth of a column of contents between them; William Reynolds has 65mm to himself and John Wilkinson a full 83mm – but this only covers his work in Shropshire.

Information and Appreciation

- There are many books and papers relating to the Wilkinson family and John Wilkinson in particular. It is useful to sort out facts from concurrent and later opinions.

- Because of the wide geographical spread of interests of John Wilkinson himself, there is no cohesion of information.

- The only museum in Britain with a useful display noting Wilkinson’s activities is at Bersham.

- The ‘Wilkinson Society’ was formed in Broseley and is now incorporated in the Broseley Local History Society. The Society has an annual lecture commemorating Wilkinson, as does the South Staffordshire Iron and Steel Institute.

- The home that he built at Castlehead has some useful information.

- Many useful papers relating to Wilkinson’s affairs can be found on websites such as ‘Broseley.org.uk’ and ‘oldcopper.org.uk’ They do get many hits each month from interested enthusiasts world-wide.

But:- |

- The importance of the Wilkinson blast furnaces at Backbarrow and Brymbo is scarcely recognised officially.

- Wilkinson’s invaluable help to Thomas Williams is not mentioned at Amlwch and Parys Mountain Copper Mine in Anglesey.

- His indispensable contribution towards the creation of the iron bridge and the name of the area is largely ignored in Ironbridge itself.

- Cornwall has a wealth of industrial history treasures but naturally prefers to acknowledge local inspiration and entrepreneurs.

- The Royal Navy museums at Chatham and HMS Victory at Portsmouth do not mention the fact that the cannon that won at Trafalgar and elsewhere were made by Wilkinson, or by others using his previously patented methods.

Literature Contradictions

There are many books and papers dealing with all or aspects of the life and times of John Wilkinson that draw on what original material has survived. At times the conclusions that the authors draw vary significantly with some interesting and confusing results. Here are just a few:

Copper interests – Butler thought that Wilkinson made poor returns while Soldon reports them as ‘among his most successful’.

Cornish Copper Company – Tann reports that Boulton deputised for Wilkinson during the formation, others quote the praise that Boulton heaped on his forceful negotiating skills with the Cornish industrialists and miners.[17]. “For God’s sake, endeavour to infuse a patriotic spirit in those that are to be the acting members in our metal company that the intention of so good an institution for the real interest of the copper trade be not defeated. There has been such egregarious mismanagement in the conduct of smelting as well as ignorance of it in the mining part that I am inclined to make another effort to save the company.”[18].

Tokens – Turner calculates that Wilkinson made high profits providing to the public a service of issuing low value tokens and others have repeated it[19] despite the fact that the calculation is based on a face value of 1d instead of the actual ½d for the big tonnage issued.

Innovation – Hayman and Horton describe John Wilkinson as ‘not an innovator himself…..’ yet most other references show a wealth of patents and other innovations introduced in every area in which he set up enterprises.

The Iron Bridge - Nikolaus Pevsner states[20]: ‘(The Bridge) was designed by Abraham Darby’. Other sources give Darby complete credit for building it[21]. In fact, Wilkinson had negotiated the support and promoted the use of iron so vigorously that it was this in particular that gained him his ‘Iron Mad’ nickname[22].

Ironworks & Coalfields

Most of the sites where Wilkinson established new ironworks were already known for their deposits of iron ore. They are listed in the ‘Gazetteer of Charcoal-fired Blast Furnaces since 1660’[23] but his technology and capital made reworking economic. Usually they were located near sources of fuel.

Most of the sites where Wilkinson established new ironworks were already known for their deposits of iron ore. They are listed in the ‘Gazetteer of Charcoal-fired Blast Furnaces since 1660’[23] but his technology and capital made reworking economic. Usually they were located near sources of fuel.

Backbarrow, Cumbria

Wilkinson gained first training from his father, Isaac. The original blast furnace is still standing. It was preserved when the subsequent steelworks on the site used it to encase a cupola furnace for remelting cast iron.

Denbighshire

Bersham

Isaac Wilkinson took over Bersham ironworks in 1753 and ran it successfully for a while. John and William joined him. In 1761 there were financial problems and Isaac moved to Bristol to enjoy retirement in what was then still the centre of the brass industry[24]. In 1763 the New Bersham Ironworks were set up. For the period 1779-1789 the total profits were £414,685, equivalent to £41,173,407 today[25]. Currently, the Bersham Heritage Centre receives about 12,000 visitors/year, with 2,500 going to the ironworks site[26].

Brymbo,

‘He had a will of iron and a temper as hot as his furnaces but he was the man who made things viable’[27].

1792 Wilkinson bought the Brymbo estate of c500 acres including three farms and Brymbo Hall. ‘Old No 1’ blast furnace was built 1796 and ran until 1894, it was then used as a sand store for the adjacent foundry and still survives. A second furnace brought output up to 4,000 tons per year. It was blown out in 1892 and demolished but the site can still be seen. By the time it was sold in 1829 the site had six steam engines mainly used for raising coal from the 41 coal pits. The works became part of Guest, Keen and Nettlefold, then British Steel Corporation until closed in 1991. It is still privately owned but a dedicated team of enthusiasts is working towards restoration when funding is available.

East Shropshire

Willey, Broseley

In 1757, Wilkinson leased the Old Willey furnaces that worked until 1774[28]. He then leased a site nearby for the New Willey furnaces and works. By 1761 the premises, machinery, buildings and stock were valued at £35,000[29]. In 1804, the New Willey closed at expiry of the lease that also required that the site be cleared. Three buildings have survived but the potential of the site has never been excavated[30].

Coalbrookdale

Wilkinson signed with the ground landlords to take over the lease of the Coalbrookdale Company’s site in 1757. When there were legal objections, he suggested a joint venture but this was rejected. He concentrated instead on the New Willey developments[31].

Snedshill

The works opened 1778 with two blast furnaces and producing 3,400 tons iron/year by 1796. It was sold in 1793 to finance Brymbo[32]. The site became part of the Lilleshall Company in 1816[33].

Hollinswood

Works on Randlay Brook, about half a mile from Snedshill, near Oakengates.

Hadley

Wilkinson bought the ground in 1791 and established the New Hadley Works near Wombridge, Shropshire with two blast furnaces served by 27 mines[34] and a works with 7 steam engines. One furnace would produce 30 tons iron/ week. The works was closed in 1820’s[35].

Hampton (Loade)

This site is about four miles south of Bridgnorth. Wilkinson is said to have owned one blast furnace here[36] but this has not been verified.

South Staffordshire

Bradley, near Bilston

Wilkinson is recognised as the founder of the South Staffordshire Iron Industry. In 1766 John set up Bradley Ironworks in Bilston, Staffordshire[37] (or c1758?)[38] over coal measures approximately 30ft thick. In 1772 he bought the manor and estate of Bradley for an 88-acre ironmaking complex of furnaces, rolling mills, brick works, pottery and canal wharf.

In 1783 the first Boulton & Watt ‘rotative’ engine was installed at Bradley[39] and in 1786, Boilermaking was started using rolled wrought iron. By 1815 there were 5,000 employees at Bilston, Bradley and Priestfield, one of the largest labour forces in Britain.

‘All those qualities of character associated with Wilkinson’s business life in the Midlands are here again demonstrated, shrewd appraisal of the situation and a nice balance of advantage to either side, imaginative foresight, and again enormous boldness and confidence’[40].

Cannon

Recognising a national need for reliable cannon that did not explode in use, Wilkinson adopted the use of solid rather than cored castings and a rigid lathe that gave reproducible circular bores. His patent, No. 1063 of 1774, was revoked by the government so that all suppliers could use the method. He retained a good share of the contracts placed.

Costings by William Wilkinson showed the cost of making cannon in quantity for the British Navy in quantity and delivering them to Woolwich Arsenal for testing was of the order of £11 per ton, of which £4 per ton was for transport [41]. He seems to have had casting and boring capacity for about 4,000 tons of cannon per year[42]. Contract prices from the Board of Ordnance were £18-£20 per ton, giving an apparent 80% profit, about £28,000 per year over a works cashflow of £44,000. There also had to be some allowance for possible loss during shipping round the coast and during the proof testing. Wilkinson’s cannon were of high quality and expected to pass the 40 test firings with ease, which meant that nearly all production was accepted, and his wealth increased.

Costings by William Wilkinson showed the cost of making cannon in quantity for the British Navy in quantity and delivering them to Woolwich Arsenal for testing was of the order of £11 per ton, of which £4 per ton was for transport [41]. He seems to have had casting and boring capacity for about 4,000 tons of cannon per year[42]. Contract prices from the Board of Ordnance were £18-£20 per ton, giving an apparent 80% profit, about £28,000 per year over a works cashflow of £44,000. There also had to be some allowance for possible loss during shipping round the coast and during the proof testing. Wilkinson’s cannon were of high quality and expected to pass the 40 test firings with ease, which meant that nearly all production was accepted, and his wealth increased.

Steam Power

‘John Wilkinson was the important third man in the firm of Boulton & Watt, though he was never a properly constituted business partner’[43]. One of the first Boulton and Watt designed steam engines was installed by John Wilkinson at the New Willey Ironworks, Broseley, Shropshire. Every effort was made to ensure success in order to impress neighbouring ironmasters. Boulton and Watt had to outsource the castings for such large machines and were very happy with the castings that Wilkinson had supplied for their trial engines, especially the close tolerances with which he could work in making large cast cylinders. None of the parts was made at Soho; everything was manufactured at Wilkinson’s works[44]. Watt supervised the erection in early 1776 and was well pleased with the excellence of the workmanship. A year later, Wilkinson also made the components for the ‘inverted’ or ‘Topsy Turvy’ engine built at New Willey to drive the cannon-boring lathe. With his experience and his well-known reputation for high quality finish-machined castings, he was the preferred supplier of main components with a 20-yr exclusive contract for cylinders for other engines[45].

Early in their development of the steam engine business in Cornwall, Boulton and Watt needed more capital than they had available. Wilkinson offered to subscribe directly but was not accepted. This left him as a usefully knowledgeable independent negotiator later, when relations between the engine makers and the Cornish mine owners became very strained. He still had their good will and confidence.

Mine owners who owed Wilkinson for the cost of castings might have a choice of payment methods. Some paid cash, others paid in kind with tons of copper and yet others with shares in their mines. Alternatively, he took payment in block tin[46]. Since the prosperity of the mines would, and did, increase when the engines came on stream, he could see a good advantage in taking shares.

There was an agreement that required engine owners to pay a royalty to Boulton and Watt, being one third of their coal savings each year. The advantage to the Cornish owners was that their engines were paid for out of revenue rather than scarce capital. When the copper prices fell, their profitability suffered and they tried to renegotiate the terms. Wilkinson was then asked to act as an honest broker.

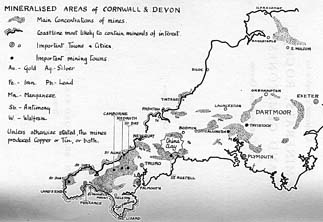

Shares in Copper Mines

In 1761 there was a large increase in the demand for copper when the Royal Navy clad the frigate ‘Alarm’ at and below the water line to prevent attack by Teredo woodworm in tropical waters. It was found that copper also reduced the growth of marine biofouling, giving a significant benefit to the speed of ships that were at sea for long periods. Wilkinson was already concerned with the business of supplying cannon for the urgent needs of the Royal Navy, such as HMS Victory, launched in 1765. He was also supplying components for steam engines for the copper mines of Cornwall.

He could therefore see more profits possible if he took an interest in the copper industry, which had many requirements that were similar to those of the iron industry.

He could therefore see more profits possible if he took an interest in the copper industry, which had many requirements that were similar to those of the iron industry.

Besides the mines in Cornwall, copper was rediscovered in 1768 at Parys Mountain in Anglesey, North Wales. For a time the mine was the largest in the world. By 1780, Wilkinson had met Thomas Williams, a solicitor of Llanidan who had gained control of most of the Anglesey copper mines, and arranged to visit the ‘Great Open Cast’ workings. He concluded:

‘It’s a curious place and affords a large field for speculation.’ [47].

Unknowingly, he had coined a phrase since used by Hope as a book title.[48]

He could see opportunities in the copper industry for the supply of steam engines, structural components and scrap iron for use in the copper precipitation tanks. After roasting, the ore was leached in one of many brick lined tanks described as 24ft x 12ft wide and 3ft deep[49]. To precipitate the copper from solution, iron was thrown in, in large quantities. If scrap was not available, cast slabs 3ft x 2ft x 2in were used. This tonnage was useful to Wilkinson as a market for scrap and as an entrance to a prospering industry. He also experimented successfully with the use of the cement copper deposited directly in his foundry for bronze cannon without further refining[50]. Heavy cast iron plates were also used on the floors of the recovery condensers for sulphur and arsenic that were attached to ore roasting furnaces. They were rapidly corroded by the acid, giving more good business.

There was also money to be made downstream of the mines in by-product recovery and the trading of copper as a commodity. Wilkinson and Williams became friends in several enterprises and benefited from their different backgrounds and training but similar attitudes to making money wherever possible. They introduced vertical integration of the industry from mine to finished product and warehousing. In 1781, they made a joint visit to Scotland for reasons not established but probably to evaluate copper mines or visit iron works[51].

While ironmaking was the first love of John Wilkinson, he made more money than could be re-invested in the iron industry with advantage. He naturally looked for better returns elsewhere. His special technical, financial and political skills were transferable to other industries and commodities. He built up a portfolio of shares in Cornish copper mines[52] such as:-

- Consolidated Mines, Gwennap, with seven Newcomen engines to be updated. At the time the Gwennap area was the hub of Cornwall’s richest mining area[53].

- United Mines, formed from six mines in the Gwennap area[54][55]

- Poldice Mine, active in 17th century, which makes it one of the earliest record in Cornwall. Poldice Mine produced over 150,000 tons copper ore, 1,500 tons tin and 2,500 tons arsenic. 1787 copper sales amounted to £11,315, compared with tin sales of £9,868. 1792 the mine produced 575 tons of copper ore in two months, sales for 1792-98 inclusive amounting to £151,471. 1793 Bolton and Watt refused, on account of the money owed them by the mine, to deliver a 66-inch double (compound) engine for the mine, odd inasmuch as the mine looked to be profitable at that time[56].

- North Downs, Gwennap

- Scorrier Mines, Gwennap

- Wheal Busy, between Redruth and Truro, Gwennap-Chacewater mining district.

- Tresaven Mine, Gwennap where the first Cornish ‘man engine’ was later installed, and

- Chasewater Mine, later part of Wheal Busy and home to the first Boulton & Watt engine in Cornwall, 1778[57].

Some of these shares may have been taken in lieu of payments. When these were bought and sold is not clear but the success of some of the mines is included by Symons in his review of Vivian’s evidence in 1799 to the Parliamentary Committee inquiring into the copper mines[58]. It is noted that many of the adventurers who invested were also equipment suppliers and happy to take their profits on what they supplied. He also mentions the common saying of the time that ‘It is much easier to throw tin into a mine than get it out!’

However, in a survey of the profits and losses made by a sample of sixteen of the many Cornish mines in the period 1792 –1798, Symons covers four of the eight mines in which Wilkinson had shares at some time. Consolidated Mines and United Mines both made a reasonable profit. North Downs and Tresaven ended up slightly in the red. This would be regarded as satisfactory at the time.

He took a one sixteenth interest in the Mona copper mine at Parys and the associated ore treatment, copper production and chemical industries together capitalised at £800,000[59].

These included

- Greenfield Copper and Brass Company, Holywell, Flintshire.

- Stanley Smelting Co, St. Helens, near Liverpool and at Swansea, South Wales.[60]

By November 1785, Wilkinson was able to say to Matthew Boulton

“All my adventuring cash is now engaged”[61] – and, we assume, giving a good profit.

Sometime around the period of 1790-1805, Wilkinson sold most of his copper shares in Cornwall[62], going liquid in order to invest in more land around his ‘retirement home’ in Castlehead and district. By the time he died, he only had Mona Mine, Anglesey, shares in his portfolio[63].

Parys Mine Current Costings

At the Parys Mine there are still 6 million tons of economic ore explored and recoverable. There is current planning permission for the extraction of 1,000 tons per day. This contains over 6% zinc, 1.30% copper, 3.3% lead and 75g silver per ton. Gold would be recovered at about 75kg per year. An investment of £22 million is required[64]. This gives a graphic update compared with the 18th century, during which the ore extracted gave a total of 130,000 tons of copper[65]. This type of project would obviously interest the likes of John Wilkinson but since the copper would be electro-won from a leach solution, possible closure of the local power station makes starting the project difficult.

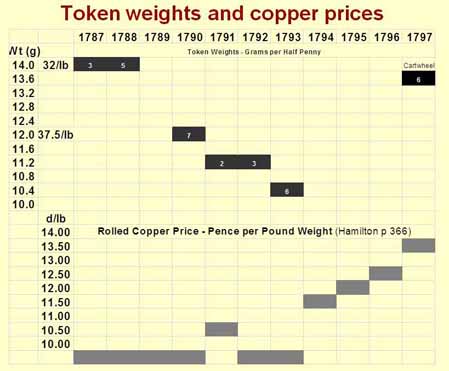

Wilkinson’s Copper Tokens

‘Wilkinson’s tokens were a show of manufacturing power and independence’[66].

During the late 18th century, the Government was not issuing small denomination coins. There was a dire shortage of money to meet demand for wages as spending money for workers who were earning only a very few shillings per week. At this time, Wilkinson employed over a thousand workers.[67] Silver coins of small value were impracticably minute. Wilkinson had encouraged his friend Thomas Williams to issue his Anglesey tokens (known as ‘Druids’) for the same practical reason as well as the fact that Williams needed another tonnage market for his copper. Wilkinson started ordering tokens for himself very shortly afterwards and continued production from 1787 to 1793. They became commonly known as ‘Willeys’

In 1781, Francis and Samuel Garbett, friends of Boulton, had undertaken an officially commissioned report on shortage of coinage but government action was slow. Boulton had to wait more than ten years for the contract so turned to other orders such as the Parys Mines token and Wilkinson tokens[68].

The tokens all bore the effigy of Wilkinson on the obverse. One design shows his hair tied back and two buttons of his coat. Some later tokens showed him with extra sets of curls to his wig and with three buttons displayed. The reverse of each token celebrated one or more of his achievements. Some are:

- The interior of a hammer shop with forgemaster using tongs to support work being struck.

- A nude figure of Vulcan seated on a low anvil with hammer raised to strike metal on a higher anvil. In the background is part of a sailing vessel. The ship is a brig and is not included in the list of those built at Amlwch[69], it is more likely to have been a Swansea boat.

- A seated blacksmith working at his anvil with a cargo ship in the background.

Most genuine tokens have been edge rolled with the inscription that covers the towns where the tokens could be redeemed: ‘Willey Snedshill Bersham Bradley’.

The Wilkinson obverse was used with many other reverses by different mints to make a wide variety of forgeries or ‘mules’[70]. Sometimes the obverse was wrongly struck with spellings such as ‘Wilkenson’ and ‘Wilkison’. The standard classification of tokens of this age is by Dalton and Hamer and there are well over a hundred ‘D&H’ numbers covering Wilkinson token varieties, forgeries and mules. From the start, the classification of the tokens was confused, being allocated to Warwickshire. Since then there have been many articles written covering the topic and it is difficult to know what to believe! They remain some of the best-known and collected examples of tokens and continue to ensure that the branding of himself that John Wilkinson initiated will never be lost.

A Token Profit?

It is not easy to show whether Wilkinson made a profit on issuing his tokens. To do so it would be necessary to know:

- Cost of production

- Cost of distribution

- Profit on sales

- Costs of redemption

- Promotional value

The promotional value came from the fact that Wilkinson’s image was on every token, an intentional, useful spin-off. The number of contemporary forgeries made might have increased his redemption costs.

Janet Butler quotes his specification as 36 tokens per pound weight. This seems to have applied only from 1780. All of the issues, from 1787 through to 1795, featured Wilkinson's portrait facing right.[71]. Boulton was able to supply the tokens to better reproducibility by striking between dies fitted with a collar that retained the diameter accurately. They were edge rolled with the legend: ‘WILLEY SNEDSHILL BERSHAM BRADLEY’ where they could easily be redeemed. Steam driven presses were used for standard tokens from 1789 and die collars could be used in steam presses from the Autumn of 1790.[72] Many tons were ordered, initially from Boulton and later from Westwood’s mint.

The 1790 Vulcan token was struck at 15cwt/week from Westwood to a total of 206,000 tokens. Seeing products from the opposition, Boulton commented to Wilkinson that he should have all tokens struck in collars. However, on December 11th 1790, Wilkinson complained to Boulton that the halfpence were four in the pound less in number than those which Westwood used to make for him.[73] In 1791 he was ordering tokens by the ton from both Westwood and Boulton. The 1792 Vulcan issue numbered 103,000 tokens. Hancock’s mint struck the tokens that have Vulcan in reverse.[74] If the Westwood tokens were struck without the use of collars it might mean that some tokens without the edge legend ‘WILLEY SNEDSHILL BERSHAM BRADLEY’ are genuine rather than fakes.

One calculation has been around for some time: [75],[76]

- Tokens at 32 to the pound weight,

- Value 2/8d[77] against a mint contract for striking at 1/11d per pound

- Profit 9d /lb,

- Return on capital approx. 40%

It is not clear where the costings came from but it is very unlikely that anyone, even John Wilkinson, could have got away with making a profit of 40% selling tokens! There were initial plans to issue tokens to the value of one penny but none was officially issued. Certainly the initial specification was for 32 tokens to the pound but the value would have been ¼d[78] which would have shown a loss of 5d per pound[79], equally unlikely.

Collected tokens have been weighed to check conformance to original specification. While ‘mint’ ones are not available, an effort was made to ensure that the sample tokens were not unduly worn. There was a check that sufficient detail still remained in the effigy. If it was not possible to count the number of buttons on Wilkinson’s coat the weight was not included. The numbers in the boxes are the sample sizes. A plot[80] shows the average weight of tokens issued for each year. Clearly the specified weight of each token diminishes with time. Obviously the makers are economising on copper ahead of the rise in price. Tokens issued during the 1790-1794 period should have netted a profit both for the mint and their customers after considering the minting, transport and distribution costs. In 1797, Boulton secured a contract from the government for minting 1d and 2d pieces (‘Cartwheel’ pennies) at the standard of the correct weight of copper for the value of the coin. This reduced the demand for commercial tokens.

Lead Mines and Works

Wilkinson bought lead mines at Minera, five miles from Bersham and Llyn y Pandy at Soughton and Mold, also in Flintshire, where John Wilkinson’s steam pumping engines made deep mining viable[81]. All the Flintshire lead was exported through the port of Chester which handled about 80,000 tons over the 20 years from 1758-1777[82].

Minera Lead Mines are in Wern Road, Wrexham. Lead mining reached its peak at Minera in 1863-4 when 6,822 tons of lead ore and 1,179 tons of zinc ore were mined. Profits were just under £70,000 for that year. Yet by 1890s the price for lead ore had collapsed. In 1910, the pumping machinery was sold and the mine closed in 1914[83]. There is a restored engine house at the top of the 1220ft deep City Shaft at Minera Lead Mine. He also owned lime kilns at Minera, Ffrith and Hope Mountain, Flintshire.

Using the lead produced, he had a lead pipe works at Rotherhithe[84], London, next to his Gun Wharf. This was subsequently run by H. J. Enthoven & Co (now part of Quexco Inc.) at their Upper Ordnance Wharf Works until the 1980s. Latterly the factory was producing lead solder alloys that were shipped down the River Thames for use as body fillers at the Ford factory in Dagenham[85]. The longevity of production from this site is quite remarkable.

Industries

These are some of the industries referred to above that are part of the vertical integration of the copper industry in which Wilkinson could obtain good returns.

- Greenfield Copper and Brass Company, Holywell, Clwyd on the North Wales coast and Cheadle, Staffordshire.

- Stanley Smelting Company[86], St Helens, Lancs and Swansea.

- Wharfs and warehouses at Chester, Cheshire and Rotherhithe, London.

- Copper metal stock sales from warehouses in Birmingham, London and elsewhere.

Iron Bridge

With the development of the Industrial Revolution in the Severn Gorge region it became essential to build another bridge across the river, higher up than that at Bridgnorth. This would link both sides of the Severn Gorge industrial area.

Thomas Farnolls Pritchard was an architect who had worked with John Wilkinson, having designed and installed a new fireplace at ‘The Lawns’ amongst other projects. He had also procured castings from Coalbrookdale.

Thomas Farnolls Pritchard was an architect who had worked with John Wilkinson, having designed and installed a new fireplace at ‘The Lawns’ amongst other projects. He had also procured castings from Coalbrookdale.

In 1773, he suggested designs for the bridge across the gorge between Broseley and Madeley. ‘Iron Mad’ John Wilkinson insisted that cast iron should be the structural material. Ironmaster Abraham Darby was glad to join the project group and most of the remainder of the initial support came from the residents of Broseley.

The group subscribed Darby’s first estimate of the cost, £3,150:-

Initial Subscribers[87] |

£/-/- |

John Wilkinson, ironmaster |

630/-/- |

Abraham Darby, ironmaster |

757/10/- |

Edward Blakeway Esq., draper |

105/-/- |

Charles Guest, grocer |

105/-/- |

Roger Kynaston, Esq. |

52/10/- |

Edward Harries Clark |

52/5/- |

Leonard Jennings, miller |

52/5/- |

John Morris, maltster |

105/-/- |

John Thursfield, surgeon |

52/10/- |

Serjeant Roden |

52/10/- |

John Hartshorn, surgeon |

52/10/- |

Thomas Farnells Pritchard, architect |

105/-/- |

John Nicholson, ‘Swan Inn’ landlord |

52/10/- |

Total |

£3,150/-/- |

(The figures quoted are in pre-decimalisation pounds, shillings and pence (£/s/d) although originally quoted in guineas where one guinea is £1/1s/-. For example, the contribution of John Wilkinson was of 600 guineas.)

Wilkinson’s persuasion and drive held together the Broseley support through a few problems and this unanimity helped the acquisition of the big names needed to push the proposal through parliament[88]. Abraham Darby agreed to build what would be the world’s first major iron bridge using his local iron foundry. To strengthen Darby’s hand, Wilkinson then passed his shares to Darby. The bridge opened in 1781. Illustrations

Had Wilkinson not held together the supporting group as he did, the bridge might have been constructed in timber or stone. Consequently, the name ‘Ironbridge’ would not have been coined for the riverside area of Madeley and the area would not have qualified for World Heritage status. As a worst scenario, the Abraham Darby furnace might still be in a similar condition to the ones at Backbarrow and Brymbo! Therefore, Wilkinson deserves significant credit from the present £76 million spent each year by the 2.6 million visitors coming to the Telford area each year[89].

Wilkinson’s ‘Trial’ – the First Iron Barge

John Wilkinson built the first canal barge made of iron for use on the River Severn and further navigation towards Birmingham, It was called ‘The Trial’ and built at Willey Wharf from cast iron plates made at the New Willey Furnace[90]. The waiting audience expected it to sink but it was successfully launched in July 1787[91]. Soon afterwards, in October 1787, some barges were built at Bradley from wrought iron sheet rolled at the mill there. Initially the cost of iron boats was higher than for those made of wood, although they outlasted the wood significantly and iron soon became the standard material for boat building.

Ships

Wilkinson needed to ship to and from ports all round the coast such as:- Amlwch, Bristol, Chatham, Chepstow, Chester, Gloucester, Greenwich, Liverpool, London Rotherhithe and Swansea. He did buy at least one seagoing ship, calling her ‘The Mary’ but later preferred to charter ships for both coastal trade and exports.

Canals[92]

Since the cost of transport of goods by canal was about one tenth of that by road, Wilkinson was a keen investor in canal building projects such as:

- Birmingham Canal Company

- Ellesmere Canal Company

- Flint Coal Canal

- River Kent – River Lune Waterway

- River Severn navigability

- Shrewsbury Canal

- Shropshire Canal Navigation

- Trent and Mersey Canal

Most were successful for years, giving a good return on capital invested until eclipsed by railways. Some are now in use again as valuable amenities.

Railways

Wilkinson laid tramways wherever needed, especially from his works to the nearest wharfage. There is no record of him trying steam traction.

Inventions and Patents

Wilkinson was the first to realise and to obtain the accuracy needed in the making of modern machinery[93]. His inventions and patents included:-

675/1753 Metallic Rollers for Grinding Grain and Sugar Canes

713/1757 Blowing Machine for Forges, Furnaces Etc.

Method of boring cylinders for steam engines using a boring bar supported by bearings each side of the work piece. This technique was not patented and was copied by Coalbrookdale and by Banks and Onions among others. He helped design the new lathe at the Soho Manufactory and provided a suitable boring bar from Bersham[94].

1063/1774 Method of Boring Cannon including making a coreless or solid casting and mounting it to rotate round the boring bar. This was such a strategic advantage that the Board of Ordinance had the patent revoked in 1779[95]. All founders used the Wilkinson method for years thereafter and it was a major contributor towards the defeat of the enemies of Britain.

1694/1789 Cutting Spiral Grooves in Bore of Cannon (Rifling) and Bolted or Winged Shot applicable thereto.

1857/1792 Rolling Metals, the use of two steam engines, one for each direction to give a reversing mill, alternately the use of one steam engine with bands operating on the up and down strokes.

1993/1794 Manufacture of Iron (use of a new furnace lower than a blast furnace and the addition of Manganese). This use of manganese was also later patented by Reynolds in 1799[96].

1799 New idea for a Chimney Boiler, beautifully coloured drawing given to William Reynolds, drawing No 47 in the possession of John Randall, 1880[97].

First to make iron chairs, horse pattens, vats for breweries & distilleries and iron pipesof all sizes[98].

First Iron Boat.

The value of each idea will depend on the novelty and the length of time for which it was useful.

Agriculture[99]

Bersham – Wilkinson aquired about 1,000 acres of agricultural land which he improved with lime from his works and good husbandry. He was the only member of the Royal Society of Arts & Manufactures to participate fully in an experimental scheme to grow good hemp.

Castlehead – Wilkinson bought 1,000 acres of land in stages, initially for the peat and then for reclamation by erecting a sea wall, drainage and irrigation.

Financial Institutions

1785 The Cornish Metal Co

Cornish miners and Thomas Williams, the Anglesey mine owner, agreed to set up a joint marketing company for copper. This would help stop the refiners from forcing prices down by what was known as the ‘ticketing’ system by which refiners made offers on batches of ore.[100] The subscribed capital was to be used to finance copper stocks but subject to an 8% sinking fund levy for payment of interest. It was arranged that Thomas Williams would have complete control of the sales of copper, an arrangement that lasted from 1787 to 1792[101]. Wilkinson obtained shares in most of Williams’ enterprises.

Warehouses were established to sell the copper where needed in Birmingham, London, Bristol and Liverpool. The Company was less successful than expected for a variety of reasons but that is not to say that it was Wilkinson who lost out. Wilkinson had sold his iron castings successfully in both Cornwall and Anglesey, had taken shares in mines in Cornwall, mines and manufactures connected with Anglesey, and also warehouses dealing in copper. He was brokering copper refining capacity and copper stocks. In addition, he could draw his 8% interest on the Company capital.

By 1787, the Company was in crisis due to falling copper prices. Boulton and Vivian visited Wilkinson at ‘The Lawns’ in Broseley before they went to see Williams and then on to London to lobby Pitt about coinage and called for Wilkinson to join them.

When the company was wound up, the shareholders regained their money[102]. The other arrangements that John Wilkinson had had bolted on to the Company structure had probably rewarded his foresight quite usefully.

1788 Birmingham Warehouse Company

In 1788, Wilkinson joined the venture to set up the Birmingham Warehouse Company with the laudable intention of providing the Birmingham industry with steady supplies copper at reasonable prices. The motive was to avoid the dependence of the Birmingham trade on supplies controlled from Bristol. The others involved were Matthew Boulton, James Watt, and John Hurd, with Thomas Williams as a preferred supplier. A subsidiary motive was to help Williams through a cash flow problem to the extent of £10,000[103]. The arrangement with Williams was that they could take delivery at advantageous Liverpool or Swansea prices, unlike other warehouses that paid significantly more for transportation costs.

Banks

To help with his business, with payments to his employees and for local benefit, Wilkinson bought in to partnership in several banks including:-

- Bradley Ironworks Bank

- Brymbo Ironworks Bank

- Eyton, Reynolds & Bishop, Shrewsbury Bank[104]

- Wilkinson & Co Bank at Bilston[105]

- Wilkinson, Startin, Smith & Smith, Union St, Birmingham.[106]

His tokens were also redeemable at the usual rate of 480 to the Sterling pound at the works offices at Willey and Snedshill.

Other Enterprises

A cartel of Severn Valley ironmasters who agreed prices during the 1760s for the sale of cast iron products[107].

The United Chamber of Manufacturers of Great Britain (with Messrs Boulton, Reynolds, Watt, Wedgwood and others[108].

Homes

In areas where Wilkinson had strong interests he invested in a domestic base. The value of these capital assets would have been additional to the value of plant and machinery mentioned when his will is discussed. Many of them passed into other hands and served many purposes. Some are still valuable assets.

‘The Lawns’, Broseley

Set up as Headquarters home with his second wife, Mary Lee, in 1763 and retained until 1800 when it was leased to John Rose of Coalport china. In private ownership, it is still a landmark building on the ‘Broseley Trail’.

Bersham Hall

Used by the National Health Service from 1974 until 1993. Demolished soon afterwards because of coal mining subsidence.

Hallfields, Bradeley

Now demolished.

Brymbo Hall

Bought with estate in 1792 for £14,000 and where he set up home for his mistress, Ann Lewis, subsequently used as company headquarters until early 20th century but demolished in 1973 to allow open pit coal mining[109].

Wrexham – The Court

Home with his first wife, Ann Maudsley.

Castle Head (Cumbria)

Built 1770 and used as home by Mary, second wife (1730-1806), then by Ann Lewis and their children. Now in use as a field studies centre.

Philanthropy

Wilkinson had a good reputation as an employer. Wherever a new works was established, cottages were built to accommodate the employees and their families. Employee pensions were given. He was happy to help the spread of technology by inviting guests to view his works. He also took on apprentices such as the son of James Watt. He is reported as giving charitable support, such as to the Madeley Poor Fund, 1795, £50[110]. At Bradley he built a chapel of iron and furnished it with a pulpit also made of cast iron.

In local schools, Wilkinson was able to overcome a shortage of slates and chalk by providing simple iron trays to hold suitable sand for writing and arithmetical practice.

He gave private support when needed, such as that of his brother-in-law, Dr Joseph Priestly in the sum of up to £10,000[111]. He was elected Broseley church warden in 1753[112] and later became High Sheriff of Denbighshire[113]

Wilkinson’s Trail

In Cumbria a Wilkinson blast furnace at Backbarrow has recently been included for preservation within an area of housing development. His main house at Castlehead is now accessible as a field studies centre and his father’s cottage still in residential use. In Cornwall there is a considerable mining and industrial heritage but the main emphasis is not surprisingly on the work of Richard Trevithick and those who developed the ‘Cornish’ steam engine.

In Denbighshire, there is a well-established popular visitor centre and museum covering the iron industry at Bersham. A small group of enthusiasts is working hard to preserve the Wilkinson blast furnace and a variety of other exhibits at nearby Brymbo.

In Shropshire, ‘The Lawns’, his house in Broseley, is in private hands but easily seen from the road. It is one of many fascinating properties of the period in the town. The ‘Old Willey’ and ‘New Willey’ sites are mainly green fields with interesting local geography. At present, John Wilkinson’s historic activities and these areas are, strangely, not promoted within the Ironbridge Gorge section of the River Severn Valley

Evaluation

As David Cannadine said to a meeting of the Newcomen Society:

‘Britain has been one of the few great technological nations’, and we await the history which both describes that and explains it. All of which is simply to say that the history of technology has for a long time been much more than the history of machinery and engineering, important though those histories undoubtedly are[114].

He implies that a combination of technical expertise with an ability to think laterally, financial acumen and a mastery of human relationships gives the recipe for success. John Wilkinson certainly had all these abilities. For a comparison with the entrepreneurs of this generation, I suggest that he would be the ‘Richard Branson’ of his day.

The benefits accrued from the activities of an industrialist can be assessed by many possible means. A spreadsheet can be constructed so that each activity can be listed together with perceived benefits in each category. To put financial benefits in perspective, each needs to be adjusted for inflation that occurred during Wilkinson’s lifetime[115] and updated to nett present values.

For the Ironbridge area World Heritage Site, the impact of Cambridge Local Area Model for estimating the economic benefits of tourism[116] in terms of numbers of visitors and employment supported has been used to obtain some useful figures[117]. These can be used to estimate the potential added benefit of including examples of Wilkinson’s activities in existing displays.

Inflation

Prices and business decisions were much affected by external events affecting the demand for materials and capital equipment. Amongst these were:

1756-1763 Anglo-French War (Seven Years War) – all major European powers involved

1775-1783 American War of Independence (Anglo French War also involving Spain and Netherlands)

1789 – 1799 French Revolution and

1792 – 1802 Wars of the French Revolution

1802 – 1815 The Napoleonic Wars

18th Century Inflation

Between 1750 and 1800 inflation was 66%. Between 1771 and 1800 inflation was 41%[118]. Then, as now, to retain the value of any capital, it had to be put to work or lose its value. Some comparisons have been made with the basic commodity prices then and now. The variations in commodity prices that happened during Wilkinson’s lifetime mean that it is not easy to make satisfactory comparisons with today’s values.

Inflation of the Price of Bread

For simplicity, when comparing the buying power of wages, the price of bread is often used. Confusion must first be avoided. Bread was commonly sold in medieval and Renaissance England as the gallon loaf(also called the half-peck loaf), which weighs 8lb 11oz (or approx. 8.7lb, 3.9kg). Later, including during the Victorian period, it was nearly always sold as the quartern loaf, made with exactly ¼stone (3½lb) of flour, and whose finished weight was approximately 4.33lb[119] (1.96kg). The modern large tin loaf weighs about 1lb 10oz (0.74kg). The price of bread varied seasonally and with the demands of various wars on manpower. In 1798 it was around 1.85d/lb[120] (old pence per pound).

Inflation of the price of Copper

During the period 1750-1810, the price of copper varied within the range £50-£120/ton. Recently it has varied within the range £3,000 to £6,000/ton, though officially priced in US dollars.

Inflation of the prices of cast iron

During the period 1750-1810, the price of cast iron varied within the range £7-£18 per ton of finished goods. Currently it sells at £150-160/ton but has been much higher within the last few years.

Present Values

There were big variations in the value of money compared with 2011 during the period 1750-1810[121], summarised in the table below that shows the multiplier to be used for individual years in each decade.

Year |

Multiplier |

1810 |

59.0 |

1800 |

63.0 |

1790 |

110.0 |

1780 |

130.0 |

1770 |

140.0 |

1760 |

150.0 |

1750 |

170.0 |

A typical multiplier of 86 has recently been used by Grenter[122] so will also be used elsewhere in this paper for continuity.[123], [124]

During Wilkinson’s lifetime:

By 1800 Wilkinson had 8 blast furnaces working[125]. To obtain a full analysis of the impact of Wilkinson it would be necessary to start with statistics such as:-

- The number of direct employees and their families

- The people benefitting indirectly.

- Capital accrued

- Infrastructure established

- Intellectual property created

- Domestic benefits

These figures are of course only sketchily available so a generalisation will be used based on estimated annual turnover.

After Wilkinson’s lifetime

Will

Estate – machinery to the value of £130,000 (2009 = £8.7m[126]) and estates.

Ann Lewis and their children to have the surname ‘Wilkinson’, an annuity and live at Castle Head.

- Duration of benefits accruing from lifetime activities.

- Family inheritance of skills and viable business.

- Inspirational effects

- Ongoing technical and tourist interest in industrial history.

- To obtain a very quick measure of comparison with the activities of contemporary ironmasters, it is interesting to look at the index to Trinder’s classic study of the Industrial Revolution in Shropshire. The three Abraham Darby’s have a 60mm depth of a column of contents between them, William Reynolds has 65mm to himself and John Wilkinson a full 83mm – but this only covering his work in Shropshire.

Benefits to the Economy and Society

Some useful estimates can be made, others will use nominal figures. In this short paper it is taken that financial indicators will be a reasonable initial measure of benefits to employees and their families. Wilkinson tried to make good provision for all his loved ones. The estate was proved at a value of £130,000 (2009 = £8.7m[127]) for machinery, not including his land and house values. He wanted Ann Lewis and their children to have the surname ‘Wilkinson’, an annuity and live at Castle Head.

To summarise his impact there is a need to consider:

- Duration of benefits accruing from lifetime activities.

- Family inheritance of skills and viable business.

- Inspirational effects

- Ongoing technical and tourist interest in industrial history.

These factors are considered together in the overall figures as estimates. English Heritage does have a methodology for estimating heritage dividend values that applies when justifying new restoration projects[128] but this is not applicable to the value of the existing site. The current value of existing relics of Wilkinson’s life is not easily estimated, frequently because of complications occurring through subsequent interesting developments. |

Robert Burns

By way of comparison with other celebrities having currently celebrated anniversaries, a recent BBC programme carried an estimate of the current value of Robert Burns (1759-1796)[129] to Ayrshire, Scotland[130]. Commemorative merchandise, food, and celebratory drink sales and service added up to about £9 million per year but tourist income brought the total to an estimated £159,000,000. In detail, this includes:

Present Value to Ayrshire |

£/y |

|

Whiskey for Burns’ Night suppers |

300,000 |

|

Burns’ Night entertainers fees |

330,000 |

|

Haggises and other food for Burns’ Night suppers |

1,320,000 |

|

Profits for organisers and caterers |

1,000,000 |

|

Merchandise including shortbread, fridge magnets, mats, souvenirs etc, mostly based on the Nasmith portrait. |

3,300,000 |

|

Extra Tourism to Burns’ Ayrshire Heritage sites |

150,000,000 |

|

Other items |

3,000,000 |

|

Total annual economic benefit per year, approximately |

159,250,000 |

|

Charles Darwin

In total contrast to the way that the present value of Burns has been costed, it seems impossible to estimate the current significance of the legacy of the painstaking revolutionary work by Charles Darwin (1809-1882). There is tourist interest in sites in Shrewsbury, Shropshire and Orpington, Kent and his books are usefully reprinted but a realistic valuation of the value of his discoveries requires a challenging methodology!

John Wilkinson

The impact of each of John Wilkinson’s activities needs to be summarised, including:

- Iron furnaces and works, including fuel, limestone etc.

- Inventions and The Iron Bridge

- Copper Interests

- Lead interests

- Transport interests

- Banks and Tokens

- Agriculture, Houses & Philanthropy

- Arbitration and Social Help

To give detailed breakdown of the impact on numbers of employees and their families, works districts, customers, transport contractors and business partners would be impractical. It is proposed to take some arbitrary figures for his times and inflate them to current values to gain an initial sense of proportion. Residuary estate figures are not entered separately, they are assumed included in the values given.

Notional Values for Industrial and Social Impact of John Wilkinson’s Interests

(These estimates are based on the considerations above, being calculated on turnover rather than profits. Most of the income would have been paid out for services and materials, to the local benefit.)

Value, c1800 |

Value, c2011 (1800 x 86) |

|

£k |

£k |

|

Iron furnaces and works, including mines for ore, fuel, limestone etc[131]. |

1,500 |

130,000 |

Inventions and Iron Bridge[132] |

103 |

825 |

Copper Interests[133] |

50 |

410 |

Lead interests |

20 |

170 |

Transport interests |

20 |

170 |

Banks and Tokens |

20 |

170 |

Agriculture, Houses & Philanthropy |

20 |

170 |

Arbitration and Social Help |

40 |

340 |

Total (approx) |

1,800 |

152,500 |

Current Notional Annual Values of the Visitor Interests of Wilkinson related sites

£/y |

|

Backbarrow Blast Furnace (private land) |

5,000 |

Willey Furnace and ironworks sites |

50,000 |

Brymbo ‘Old No 1’ Blast Furnace (private land) |

25,000 |

Castlehead Field Studies Centre |

50,000 |

Bersham Heritage Centre and Ironworks, Minera lead mine |

1,000,000 |

British Waterways canals (small proportion) |

10,000 |

Parys Copper Mine & Amlwch Heritage Museum (fraction) |

25,000 |

HMS Victory cannon, Portsmouth (Fraction) |

100.000 |

Ironbridge World Heritage Centre, (Telford Corporation) (Fraction) |

50,000,000 |

Conclusions

This paper has presented a very brief survey of the very wide spread of the industrial and other interests of John Wilkinson abstracted from an extensive range of literature. It demonstrates the wide geographical scope of his work and the limitations that this places on the establishment of a ‘Wilkinson Trail’ of sites for interested enthusiasts. Notional estimates for the value of his works are given and updated to 2011 values. A separate calculation has been made for the notional current value of income by area from visitors interested in his legacy. The latter figure is higher than might be expected after it is realised that, without the negotiating skills of John Wilkinson, the Iron Bridge would very probably not have been made of iron.

This summary of the interests of and benefits accruing from John Wilkinson might form the basis for a more extensive analysis. It seems unlikely that more sources of original data will now appear but the work would still be a valuable long-term project.

Acknowledgements

The author is very grateful for useful comments and help given by Mark Bramall, Neil Clarke, Steve Dewhirst, John Freeman, Steve Grenter, Peter King and David Lake.

References

(Some earlier work, some not yet seen personally, is included in ‘Researching John Wilkinson Literature’, a list of relevant books and library collections prepared by Neil Clarke and printed in J Wilk. Soc. 1984, No 12. and reprinted below.)

Alexander, Eric, ‘John Wilkinson’s Trade Connections’, J. Broseley Loc. Hist. Soc, 30, 2008, pp34-38. (Broseley Local History Society includes The Wilkinson Society)

Barker, Richard, ‘Iron Ships in Green Fields’, J. Broseley Local Hist. Soc, 30, 2008, pp20-33.

Barker, Richard (Ed.) ‘Wilkinson Studies’ Merton Priory Press, Vol. I 1991, 67pp, ISSN 0962-9173, Vol. II, 1992, 100pp, ISBN 0 9520009 0 3,

Bennett, John (ed.), ‘Minera Lead Mines and Quarries’, Wrexham Maelor Borough Council, 1995, 101pp, ISBN 0 952 55 29 0 6.

Bloy, Marjie, ‘The Speenhamland System’, (1795 poor law allowance standards),

[http://www.victorianweb.org/history/poorlaw/speen.html]

Braid, D.H.P. ‘Gun Boring from the Solid’ Trans. Newcomen Soc. 58 (1986) pp. 45-58.

Butler, Janet, ‘John Wilkinson’, PhD thesis, unpublished draft, Coalbrookdale Library.

Callcut, Vin, ‘John Wilkinson – Copper King?’, J. Broseley Loc. Hist. Soc, 27, 2005, pp2-28 (http://www.broseley.org.uk/Docs/journal2005.PDF) and in full at: Copper King?

Carlisle, J A & Carlisle, J, ‘John Wilkinson, Ironmaster’(http://www.corvedale.previewurl.com/history/john_wilkinson_and_the_snedshill.htm)

Challoner, W. H., ‘The Agricultural Activities of John Wilkinson, Ironmaster’, British Agricultural History Society, 1957 (5) Pt 1, (http://www.bahs.org.uk/05n1a4.pdf)

Challoner, W. H. ‘John Wilkinson as Note Issuer and Banker’, Seaby's coin and medal bulletin (Dec. 1948), pp. 550-553

Challoner, W. H. ‘New lights on John Wilkinson's token coinage’, Seaby's coin and medal bulletin (July 1948), p. 306-308.

Challoner, W. H., ‘Dr Joseph Priestly, John Wilkinson and the French Revolution, 1789-1802’, Trans Royal Hist. Soc. 8, 1958, pp21-40.

Challoner, W. H., ‘The Skilled Artisan 1750-1850’ The Historical Association, 1969, 16pp.

Clarke, Diana, ‘The Spirit of the Age: Ideas and Movements of the Eighteenth Century and John Wilkinson’, J Broseley Loc. Hist. Soc. 24, 2002, pp2-18. (http://www.broseley.org.uk/Newsletters/journal2002-web.PDF)

Clarke, Neil ‘John Wilkinson’s Transport Interests’, J. Broseley Loc. Hist. Soc, 30, 2008, pp3-14.

Cossons, Neil & Trinder, Barrie, ‘The Iron Bridge’, Moonraker Press, 1979, 139pp. SBN 239.00187.7.

Dalton, R. & Hamer, S. ‘The Provincial Token Coinage of the 18th Century’., Allan Davisson's 2004, 566pp.

Davies, Ron, ‘John Wilkinson – Ironmaster Extraordinary’, 2nd Ed., Broseley Local History Society, 26pp. ISBN 0 9504999 5 1.

Davies, Stanley A. ‘Isaac Wilkinson (c. 1705-1784) of Bersham, Ironmaster and Inventor’, Trans. Newcomen Soc. 27 (1949) pp69-72.

Dawson, Frank, ‘John Wilkinson, King of the Ironmasters’ Unpublished book, Broseley Local Hist. Soc, 2009, 118pp.

Dawson, Frank, ‘The Significance of the Women in John Wilkinson’s Life’, J. Broseley Loc. Hist. Soc, 30, 2008, pp39-44.

Dickinson, H. W. ‘Matthew Boulton’, TEE Publishing 1936, reprinted 1999, 218pp. ISBN 85761 112 8.

Dickinson, H. W. and Jenkins, R., ‘James Watt and the Steam Engine’, First Edition 1927, Second edition 1981, reprinted Encore Editions 1989, 415pp. ISBN 0-903485-92-3

English Heritage, ‘The Heritage Dividend Methodology: Measuring the Impacts of Heritage Projects’, c2005, 27pp. http://www.helm.org.uk/upload/pdf/Heritage-Dividend-Methodology.pdf?1243266308

Forward, B A. ‘The Early History of the Cylinder Boring Machine’ Trans. Newcomen Soc. 5 (1924) pp24-38.

Grenter, Stephen, ‘The Wilkinsons at Bersham’, J Broseley Loc. Hist. Soc. 30, 2008, pp14-19.

Harris, J R, ‘The British Iron Industry, 1700-1850’, Palgrave Macmillan, 1988 96pp.

Harris J. R., ‘The Copper King, A Biography of Thomas Williams of Llanidan’, Liverpool University and University of Toronto Press, 1964, 194pp

Hayman, Richard & Horton, Wendy, ‘Ironbridge: History and Guide’. Tempus Publishing, 199, 160pp. ISBN 0 7524 1460 7.

Herfindal, Orris C. ‘Copper Costs and Prices: 1870-1975’, Johns Hopkins Press, Baltimore. 1959, 260pp, Library of Congress Cat Card 59-15390.

Hope, Bryan D, ‘A Curious Place, The Industrial History of Amlwch (1550-1950)’, Watch House Books, Moelfre, 1994, 176pp. ISBN 0 9535268 0 1.

Lentin, G.L.L., ‘Letters on The Island of Anglesey Copper Mine and Associated Foundries and Factories’, Siegfried Lebrecht Crusius, Leipzig, 1800, translated by Rothwell, Nancy, Amlych Industrial Heritage Trust, 2007.

Mantoux, Paul ‘The Industrial Revolution in the Eighteenth Century. An Outline of the beginnings of the modern factory system in England’. Methuen, 1964 528pp. ISBN 0-416-68240-5.

Morton, G. R. & Smith, W. A., ‘The Bradley Ironworks of John Wilkinson’, J.I.S.I. 1966, July.

Nelson, Robert L, ‘Price of Bread: Poverty, Purchasing Power and the Victorian Labourer’s Standard of Living’, [http://www.victorianweb.org/history/work/nelson1.html]

Pee, Ralph and Hawes, Maurice, ‘John Wilkinson and the Two Willey Ironworks’, J. Wilkinson Soc. (now incorporated in Broseley Local History Soc.) 16, 1988.

(http://www.broseley.org.uk/wilkfiles/THE%20TWO%20WILLEY%20IRONWORKS.htm)

Pye, Charles, ‘Provincial Copper Coins or Tokens: Issued Between the Years 1787 and 1796’ Nicho;s & Egerton, 1797

Randall, John, ‘Broseley and its Surroundings’, Salopian and West Midland Journal, 1879, 328pp. (available in CD-ROM format from Broseley Loc. Hist. Soc.).

Randall, John, ‘History of Madeley’, 1880, reprinted by Salop County Library, 1975, 387pp. ISBN 0 903802 02 3

Randall, John, ‘Our Coal and Iron Industries; the Wilkinsons’, Randall, 1876, reprinted Barrow News & Mail, 1917, 57pp & 14pp appendix.

Randall, John, ‘The Wilkinsons’, book published 1876.

Reeve, Robin M. ‘The Industrial Revolution 1750-1850’, University of London Press 1971, 270pp. ISBN 0 340 07349 7

Riden, Philip, ‘A Gazetteer of Charcoal-fired Blast Furnaces in Great Britain in use since 1660’, Merton Priory Press, 1987, 1993, 166pp, ISBN ) 9520009 1 1.

Rogers, Cedric, ‘A Collector’s Guide to Minerals Rocks and Gemstones in Cornwall & Devon’, D. Bradford Barton, Truro, 48pp.

Rogers, D L ‘Shropshire Canals’. Shrewsbury & Newport Canals Trust, Issue 10, May 2003, [http://www.sncanal.org.uk/10%20-%20May%202003.pdf]

Rolands, John, ‘Copper Mountain’ , Anglesey Antiquarian Society, Llangefni, 1966, 201pp.

Rowlands, Eryl Wyn, ‘Masts and Shafts, The Story of the Town and Port of Amlwch 1793-1913’, Millenium Working Party, Amlwch, 2000, 28pp.

Soldon, Herbert C., ‘John Wilkinson (1728–1808) English Ironmaster and Inventor’ Edwin Mallen Press, New York 1998, 380pp, c170 refs. (ISBN: 0-7734-8268-7)

Schmitz, C. J., ‘World Non-Ferrous Metal Production and Prices 1700-1976’. Frank Cass 1979 425pp. ISBN 07146 3109 4.

Selgin, George, ‘Good Money: Birmingham Button Makers, the Royal Mint and the Beginnings of Modern Coinage, 1775-1821’. Independent Institute, 1957, 2008, 345pp. ISBN-13: 978-0-472-11631-7.

Symons, John, ‘The Copper Mines of Cornwall: Property and Profit’, CHN Conference 2002, Worcester, summarising the report of the Parliamentary Committee on the Copper Industry, 1799.

Tann, Jennifer, ‘Boulton and Watt's Organisation of Steam Engine Production before the opening of Soho Foundry’ Trans. Newcomen Soc. 49 (1977) pp.41-56

Tann, Jennifer, ‘Riches from Copper: the Adoption of the Boulton & Watt Engine by Cornish Mine Adventurers’, Trans Newcomen Soc. 67 (1995), pp.27-52.

Telford & Wrekin Economic Baseline 2007 ‘Transforming Telford’

(http://www.telford-development-agency.com/_library/download/www/Files/Telford%20Wrekin%20Economic_Profile_2007.pdf)

Telford & Wrekin Council, ‘Ironbridge Gorge Management Plan: Section 2 Description and Significance of the World Heritage Site’ (http://www.telford.gov.uk/NR/rdonlyres/945FB6AB-DA90-431B-A8EE-225BE18573ED/0/description.pdf)

Trinder, Barrie, ‘The Industrial Revolution in Shropshire’, Phillimore & Co. Ltd., 1981, 308pp, ISBN 0 85033 428 4.

Turner, Wayne, ‘John Wilkinson’s Trade Tokens’, J. Wilkinson Soc. 1974, 2, 10-12.

Uglow, Jenny, ‘The Lunar Men’, Faber & Faber, London 2002, 588pp. ISBN 0-571-21610-2.

Webb, Dominic ‘Inflation, the value of the Pound 1750-2005’ House of Commons Research Paper 06/09, 13/02/06. (http://www.parliament.uk/commons/lib/research/rp2006/rp06-009.pdf)

Researching John Wilkinson Literature

Manuscript sources in public collections:

Birmingham Reference Library: Boulton & Watt collection

Correspondence with John and William Wilkinson List of John Wilkinson's engines

British Museum: Egerton M.S. 1941

Annotated drawings of John Wilkinson's blowing engine of 1776

Ironbridge Gorge Museum Trust: Lilleshall Company Collection

Leases, agreements and map relating to Hollinswood, Snedshill and New Hadley Ironworks

National Library of Wales: John Wilkinson's Estates

A volume containing balance sheets of Wilkinson's estates, 1820 - 23 (MSS. 10822E) A group of accounts relating to Wilkinson's estate, 1825 - 31 (MSS. 18023E)

Shropshire Record Office: Forester Collection (1224)

Leases, accounts and correspondence relating to John Wilkinson and the New Willey Company. Shackerley Collection (1781): correspondence of Gilbert Gilpin with John and William Wilkinson

Warrington Public Library:

Priestley Correspondence Letters, chiefly written to John Wilkinson by Joseph Priestley.

John Randall, ‘The Wilkinsons’ (1876)

A.N. Palmer, ‘John Wilkinson & the O1d,Bersham Ironworks’ (1899)

H.W. Dickinson, ‘John Wilkinson: Ironmaster’ (1914)

W.H. Chaloner ‘John Wilkinson: Ironmaster’ (History Today, May 1951)

W.H. Chaloner ‘The Agricultural Activities of John Wilkinson, Ironmaster’ (Agricultural History Review, v, 1957)

W.H. Chaloner ‘Dr. Joseph Priestley, John Wilkinson and the French Revolution’ (Transactions of Royal Historical Society, viii, 1958)

W.H. Chaloner ‘Isaac Wilkinson: Potfounder’ (Studies in the Industrial Revolution, 1960)

W.H. Chaloner ‘The Life of Gilbert Gilpin, chief clerk at Bersham Ironworks, near Wrexham, 1786 - 96, and his relations with the Wilkinson brothers’ (National Library of Wales Journal, ii, 1960).

G.R. Morton & W.A. Smith ‘The Bradley Ironworks of John Wilkinson’ (Journal of the Iron & Steel Institute, July 1966)

W.A. Smith ‘John Wilkinson & the Industrial Revolution in South Staffordshire’ (West Midland Studies,5, 1972).

Ralph Pee ‘The World's First Iron Boat’ (Shropshire Magazine, July 1972)

Ralph Pee ‘The Broseley Home of John Wilkinson’ (J. Wilk. Soc., 1, 1973)

Wayne Turner ‘King of the Ironmasters’ (J. Wilk. Soc., 1, 1973)

Wayne Turner ‘John Wilkinson's Trade Tokens’ (J. Wilk. Soc., 2, 1974)

Maurice Hawes and Ralph Pee ‘John Wilkinson and the two Willey Ironworks’ (Wilkinson Society Monograph, No. 1, 1974)

N. J. Clarke ‘New Hadley Colliery & Ironworks’ (J. Wilk. Soc. , 7, 1979)

Ralph Pee ‘The New Willey Ironworks: a reappraisal of the site’ (J. Wilk. Soc. 9, 1981).

Cyril McCoombe ‘Report on the current state of the Wilkinson Monument at Lindale, Cumbria.’ . . (Foundry Trades Journal, 1981). (see also ‘Wilkinson Monument Restored’, J. Wilk. Soc. 13 p13.

(Above list prepared by N. J. Clarke. First printed in J Wilk. Soc. 1984, No 12)

[1] Randall, Broseley p112.

[2] Randall ‘Madeley’, p109.

[3] Luter, P – ‘at a meeting of the Chamber of Manufacturers in London, Wilkinson baled out William Reynolds with £100’ (private communication).

[4] Davies, quoting Randall.

[5] Dawson, Ch 4.

[6] Randall, ‘Madeley’ p64.

[7] Dawson, Ch 8.

[8] Dawson, Ch 11.

[9] Selgin p52.

[10] Dawson, F. ‘Significance of the Women in Wilkinson’s Life’.

[11] Alexander.

[12] Alexander.

[13] Uglow.

[14] Harris, ‘Copper King’

[15] Uglow.

[16] Harris, J R,

[17] Soldon, p 281.

[18] Butler

[19] Soldon.

[20] ‘Shropshire’, Nikolaus Pevsner 1958 & 1979.

[21] For example, the plaque on the bridge placed there by English Heritage.

[22] Berthoud, Michael, J Bros. Hist. Soc, 1996 Vol. 18.

[23] Riden, Philip.

[24] Davis.

[25] Grenter, p20.

[26] Steve Grenter, private communication.

[27] Uglow, p253

[28] Davis p6.

[29] Wilk. Studies II p95.

[30] Pee and Hawes.

[31] Dawson, F, draft p21.

[32] (http://www.british-history.ac.uk/report.aspx?)

[33] Trinder, B.

[34] Soldon, p77.

[35] Carlisle.

[36] Soldon, p75.

[37] Bilston, http://www.wolverhamptonarchives.dial.pipex.com/local_industry_3.htm

[38] Bilston, http://www.wolverhamptonarchives.dial.pipex.com/local_industry_3.htm

[39] Selgin p50.

[40] Dawson, Ch 7.

[41] Soldon, p80.

[42] Soldon, p 85.

[43] Dawson, ‘King of the Ironmasters’, forward.

[44] Dickinson & Jenkins p44.

[45] Grenter, p19.

[46] Butler.

[47] Butler.

[48] Hope, B.

[49] Lenten, Letter 7, p24.

[50] Lentil, Letter 7 p25.

[51] Butler.

[52] Butler.

[53] http://www.genuki.org.uk/big/eng/Cornwall/Gwennap/

[54] West Wheal Virgin, Wheal Lovelace, Wheal Fortune, Ale & Cakes, Poldory and Wheal Cupboard (Barton p23.)

[55] http://www.gwennap-opc.com/mining_in_gwennap.htm#Mines%20Of%20%20The%20Gwennap%20Area

[56] http://www.aditnow.co.uk/mines/Poldice-Copper-Mine.

[57] http://www.poldark-mine.co.uk/heritage.htm.

[58] British Parliamentary papers

[59] Harris, J R, ‘Copper King’, p52.

[60] Harris, J R, ‘Copper King’, p52.

[61] Butler

[62] Butler

[63] Soldon, p294.

[64] (http://www.angleseymining.co.uk/amplc/ParysMine/Paryshistoricaloutline.htm)

[65] Harris, J R, ‘Copper King’ p 52.

[66] Uglow P419

[67] Selgin Ch1 p3.

[68] Harris p88.

[69] Rowlands.

[70] ‘Mules’ are tokens struck from dies where the obverse and reverse were not originally intended to match.

[71] Dell, John, Victoria Numismatic Society, http://victoria.tc.ca/Recreation/VNS/wilktoken.htm

[72] Selgin Ch2 p5.

[73] Turner, Wayne.

[74] Dell, John, (http://victoria.tc.ca/Recreation/VNS/articles/wilkinson/wilktoken.htm)

[75] Turner, Wayne.

[76] (http://www.broseley.org.uk/wilkfiles/Wilkinson%20tokens.htm)

[77] Two shillings and eight pence of pre-decimal money, just over half a crown (2/6d), now equivalent to 13p.

[78] a farthing instead of the nominal value of a ha’penny.

[79] 5d = five old pence = approximately 2½ new pence.

[80] In PowerPoint presentation and at [http://www.oldcopper.org.uk/Pages/wilk%20token%20weights.htm]

[81] (http://www.wrexham.gov.uk/english/heritage/minera_lead_mines/mining_heyday.htm.)

[82] Lentin, Letter 10, p48.

[83] (http://www.wrexham.gov.uk/english/heritage/minera_leadmines.htm)

[84] http://www.southwark.gov.uk/Uploads/FILE_10435.pdf p39.

[85] http://www.southwark.gov.uk/Uploads/FILE_21325.pdf

[86] http://eprints.worc.ac.uk/293/5/5._Ch_4.pdf http://eprints.worc.ac.uk/293/

[87] Cossons and Trinder.

[88] 16 Geo III, c.17 (Mantoux p307)

[89] Telford & Wrekin Council.

[90] Barker.

[91] Randall, Broseley, p108.